Pulling type hot-reclaimed Maintenance car claimed Maintenance car HOTBOX-S1000-I – EROMEI

Pulling type hot-reclaimed Maintenance car claimed Maintenance car HOTBOX-S1000-I – EROMEI Detail:

Rapid heating and stirring

Asphalt Mixture Recycling

Hot Asphalt Heating and Insulation

Ready to ship

HOTBOX-S1000-I

HOT-RECLAIMED COMPREHENSIVE MAINTENANCE CAR (TRAILER)

HOTBOX-S1000-I trailer-mounted thermal regeneration maintenance vehicle is a professional comprehensive asphalt road thermal regeneration repair equipment. Mainly consists of power system and electric control system,walking system (trailer chassis), drum silo mixing system, hot asphalt heating and heat preservation and adding system, smoke filter system,drum silo hot air circulation heating system, emulsified asphalt spraying system (optional), etc.

OEM Supply China Pothole Repair Asphalt Heater and Construction Machinery, Our solutions are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Before

After

HOTBOX-S1000-I

● Higher heating efficiency

The drum of the equipment adopts the hot air circulation heating mode to ensure that the heating air flow can directly and effectively heat the asphalt mixture, and cooperate with the drum mixing function to achieve the uniform heating of the asphalt mixture and improve the heating efficiency. The first heating time is 20-25min, and the continuous heating time is 15-20min, hot asphalt mixture can be produced quickly in the construction site, and materials can be provided for repairing pavement diseases in time.

● Hot asphalt heating hose

It is equipped with 4.8m hot asphalt heating hose, which is used for the transportation of hot asphalt. The temperature is accurately controlled by the temperature controller to ensure that the temperature of asphalt does not decrease during the filling process and to avoid the asphalt solidification in the hose.

● Stable and efficient burner

Diesel burner adopts imported brand RIELLOto ensure more stable operation and higher heating efficiency.

● Filtering and dedusting device

The equipment is equipped with a whirlwind dust removal filter system, which can filter the smoke and dust generated inside the drum and enter the drum again. This can not only prevent the dust from polluting the environment, but also avoid heat loss, reduce the heating time of the asphalt mixture, and improve the heating efficiency.

● Powerful, durable and stable

The equipment uses high-performance generator set (KOHLER engine imported from the United States) to provide power to the whole equipment (220/380V), so that the equipment has a continuous power input, strong power generator set, stable voltage and power output, while Low engine fuel consumption. The equipment has a long service life and lower cost.

● Convenient transportation

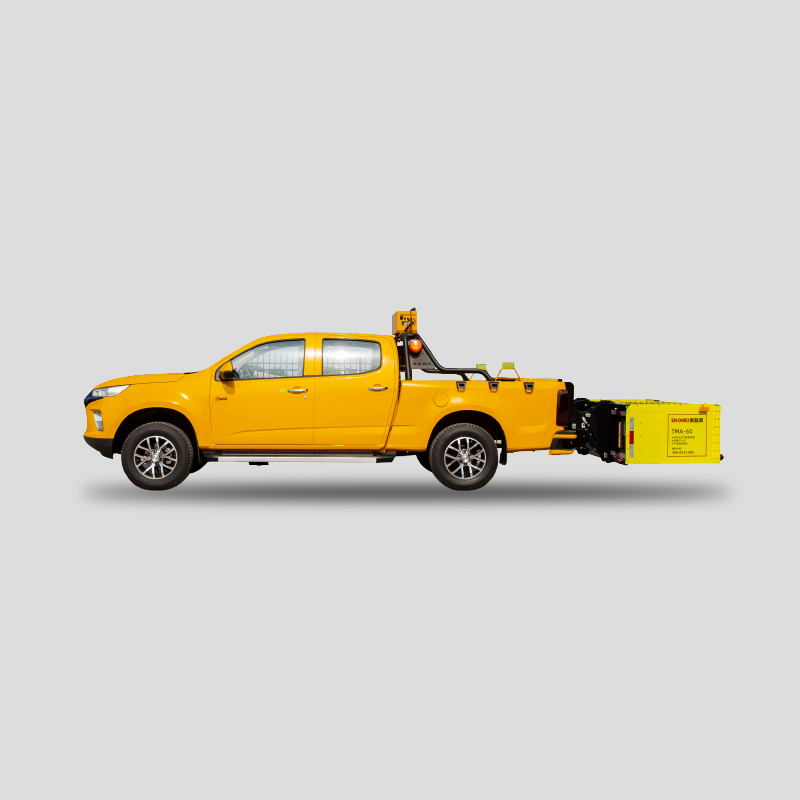

The equipment adopts trailer chassis, which makes transportation more convenient. At the same time, it is equipped with professional truck tires and service brake devices to ensure the safety of trailer driving.

CONSTRUCTION PROCESS

The pits and grooves have been eroded by rain for a long time, which has caused road damage more and more.

Crush the pits and grooves, put the waste asphalt into the equipment for constant temperature heating and regeneration.

Spray emulsified asphalt, regenerate the finished asphalt mixture, pave the pit and flatten it.

Effectively prevent rain erosion for 3-5 years after pavement repair.

① Crush the damaged asphalt pavement

② Recycled old material from hopper to roller heating box

③ Set temperature for heating and regeneration

⑤ Compacted asphalt

④ Discharge and pave

⑥ Patching complete

SCOPE OF APPLICATION

It can be used to repair potholes, ruts, oil bags, cracks, damaged roads around manhole covers, etc.

Sinking

Loose

Cracked

Pothole

Highways

National roads

Urban roads

Airports

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Pulling type hot-reclaimed Maintenance car claimed Maintenance car HOTBOX-S1000-I – EROMEI , The product will supply to all over the world, such as: Southampton, Myanmar, Bolivia, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!