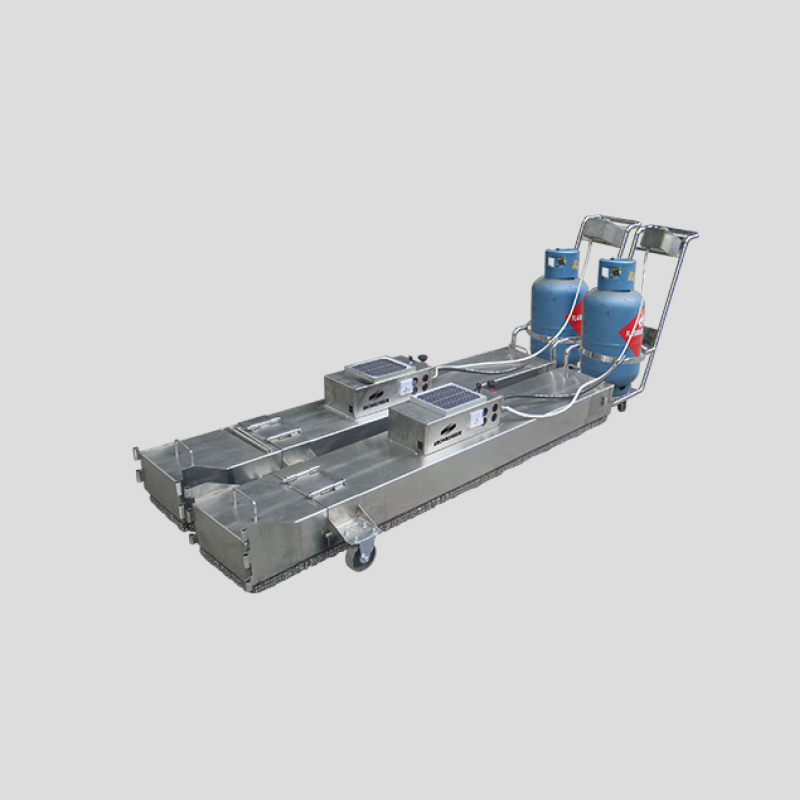

Hand-held propelled Asphalt Hotbox Recycler

Zone Heating

Automatic power cut-off

Blue light thermal radiation heating technology

liquefied gas function

HAND-HELD

PROPELLED ASPHALT HOTBOX RECYCLER

The equipment is used for repairing pothole of asphalt pavement to ensure the good joint between the repair area and the original pavement, effectively prevent water seepage and to extend the service life of the road.

Before

After

• Zone heating structure

The rear heating plate adopts intermittent heating to prevent overheating and aging in the heating process. At the same time, the heating plate can be divided into left and right areas to be heated individually or integrally. According to the area of the repair area, it can be flexibly selected to reduce repair costs.

• Higher heating efficiency

The equipment uses the unique blu-ray thermal radiation principle of liquefied natural gas to heat the road surface, to ensure the full use of heat, and the heating efficiency is higher. The asphalt road surface can be heated to over 140 ℃ in 8-12 minutes, and the heating depth can reach 4-6cm.

PRODUCT DESCRIPTION

• Safe and reliable during construction

During the construction, the heating plate shall be heated in a closed way, and the heat loss shall be blocked through the insulation layer. The temperature on the upper surface and around the heating plate is low, so as to ensure the safety of the construction personnel to the greatest extent. At the same time, the ignition device works continuously to ensure the full combustion of gas.

• Cold material heating function

The old materials can be recycled on site, and the finished cold materials can also be heated on site, without too much construction equipment, to avoid material waste and reduce repair costs.

① Heating damaged asphalt pavement

② Raking and adding new asphalt

③ Reheat

④ Spray emulsified asphalt

⑤ Compacted asphalt

⑥ Patching complete

CONSTRUCTION PROCESS

Sinking

Loose

Cracked

Pothole

SCOPE OF APPLICATION

It can be used to repair potholes, ruts, oil bags, cracks, damaged roads around manhole covers, etc.

Highways

National roads

Urban roads

Airports

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur